Friction Bolts, Split Sets and Combi Washers

Our friction bolts, split sets, and combi washers are essential rock support systems used in mining, tunneling, and underground construction to provide stability and reinforcement in rock formations. These products are designed to withstand high loads, provide immediate support, and enhance safety in challenging ground conditions. Here is important product information and specifications for friction bolts, split sets, and combi washers

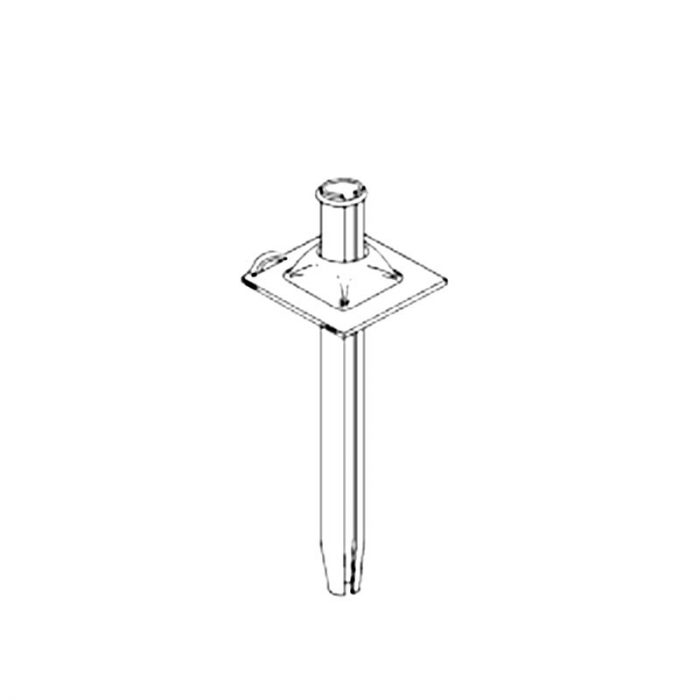

Friction Bolts

Material: Friction bolts are typically made from high-strength steel, ensuring excellent load-bearing capacity and durability. They are provided either in a Black (uncoated), Hot Dipped Galvanised (HDG), Thermal Zinc Diffused (TZD) or 3 CR12 High Memory Stainless Steel.

Design: They feature a threaded body with a grouted length and a head for applying tension. The threaded body provides a frictional connection with the surrounding rock, creating support and stability.

Installation: Friction bolts are installed by drilling a hole into the rock formation, inserting the bolt, and applying tension by torquing the head. The tension generates frictional forces that anchor the bolt securely in the rock.

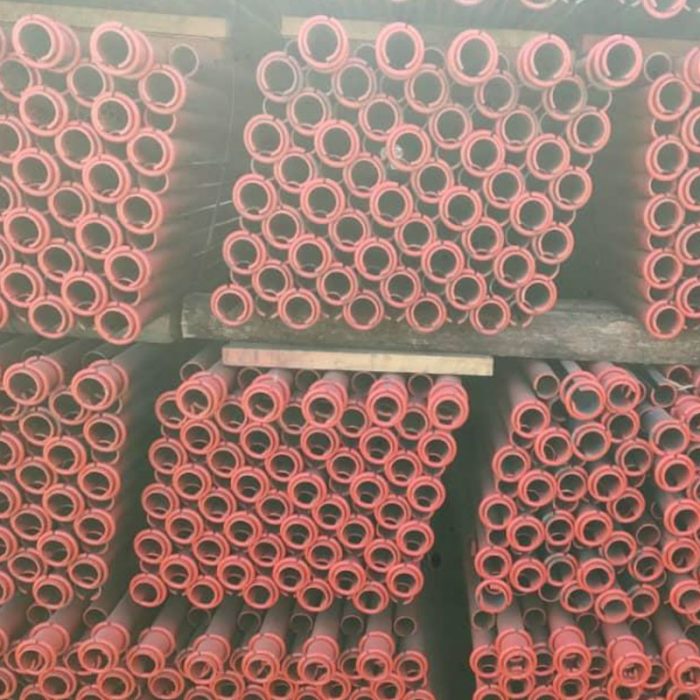

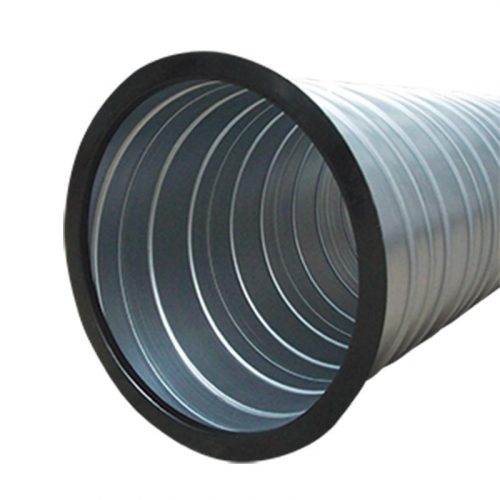

Split Sets

Material: Split sets are usually made from high-strength steel, offering exceptional load-bearing capabilities and resistance to deformation. Availablein a Black (uncoated), Hot Dipped Galvanised (HDG), Thermal Zinc Diffused (TZD) or 3 CR12 High Memory Stainless Steel.

Design: Split sets consist of a tube-like body with longitudinal splits along its length. When inserted into a drilled hole, the split sets expand and exert radial pressure on the surrounding rock, providing effective support.

Installation: Split sets are installed by inserting them into a drilled hole using an insertion tool. Once in place, the split sets expand and conform to the shape of the hole, creating a secure rock reinforcement.

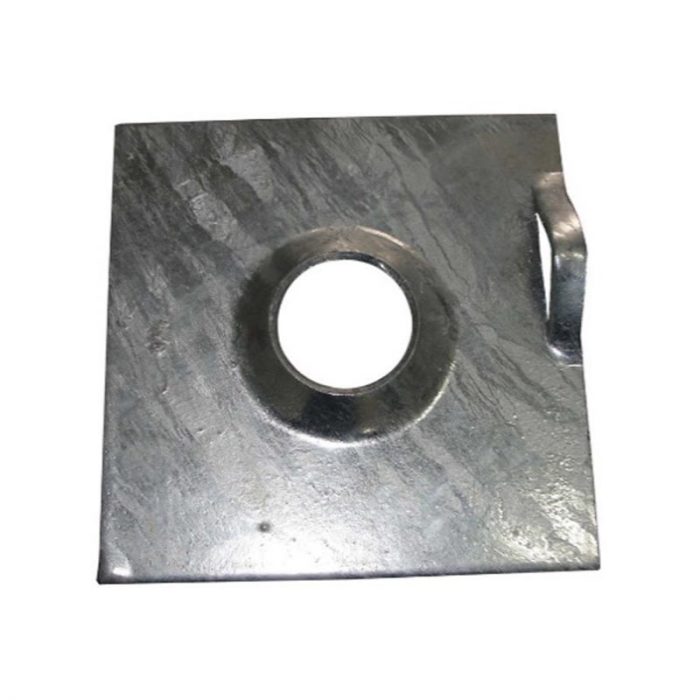

Combi Washers

Material: Combi washers are available in a Black (uncoated), Hot Dipped Galvanised (HDG), Thermal Zinc Diffused (TZD) or 3 CR12 High Memory Stainless Steel.

Design: Combi washers have a flat circular shape with raised ribs or teeth on one side. They are used in conjunction with friction bolts or split sets to provide additional load-bearing capacity and improve anchorage.

Installation: Combi washers are placed on the head of the friction bolt or split set before torquing. The raised ribs or teeth grip the surrounding rock surface, enhancing the overall anchorage and support.

Features and Benefits

Immediate Support: Friction bolts, split sets, and combi washers provide immediate support upon installation, improving safety and stability in underground environments.

Load-Bearing Capacity: These rock support systems are designed to withstand high loads and ground movements, ensuring reliable reinforcement in challenging rock formations.

Versatility: Friction bolts, split sets, and combi washers can be used in various ground conditions, including hard rock, soft rock, and unstable formations.

Easy Installation: The installation process is relatively straightforward and can be carried out with standard rock drilling equipment, reducing installation time and costs.

Customization: We offer a range of sizes and specifications for friction bolts, split sets, and combi washers to accommodate different project requirements.

Certification and Compliance: Our Friction Bolts, Split Sets; Combi Washers are designed and manufactured to meet industry standards and regulations for safety and performance. They undergo testing and quality control processes to ensure their compliance with relevant national and international standards.

Please note that the specific product information and specifications may vary depending on the manufacturer and the specific design of the friction bolts, split sets, and combi washers.

For detailed information and technical specifications related to your specific needs, we recommend contacting our sales team or referring to our product documentation.

For further assistance or to discuss your specific rock support requirements, please feel free to reach out to our dedicated team.

For additional documentation on the above products please visit our DOWNLOADS page.

- Additional information

Additional information

| Standard Diameters: | • 33mm • 39mm • 46mm |

|---|---|

| Standard Lengths: | • 0,6m • 0,9m • 1,2m • 1,8m • 2,4m • 3,0m |

| Material Options: | • S420 – High Memory Steel • 3CR12 – Stainless Steel High Memory |