Straining Wire / Engineering Steel Wire Rope

Our Straining Wire Rope, also known as Engineering Wire Rope, is designed for heavy-duty applications that require high tensile strength, durability, and resistance to extreme conditions. It is commonly used in construction, engineering, mining, and other industries where reliable and robust wire rope is essential. Here is important product information and specifications for our Straining Wire Rope

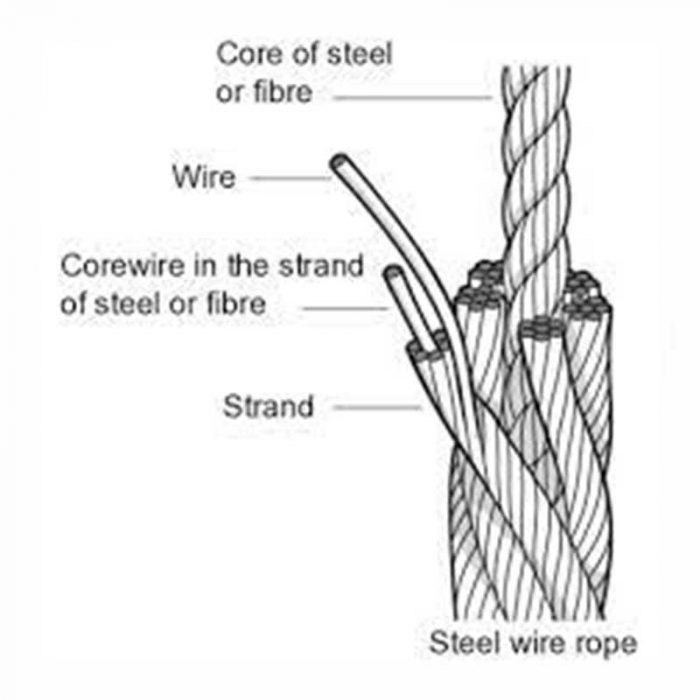

Construction and Material: Our Straining Wire Rope is typically constructed with a core and multiple strands. The core provides stability and strength, while the strands, made of high-quality steel wires, contribute to the overall tensile strength and load-bearing capacity of the rope. The steel wires are usually galvanized or stainless steel for enhanced corrosion resistance.

Wire Rope Configurations

We offer a variety of configurations for our Straining Wire Rope to suit different application requirements:

Single-Layer Wire Rope: This configuration consists of one layer of strands wrapped around the core, offering strength and flexibility.

Multi-Layer Wire Rope: In this configuration, multiple layers of strands are laid over the core, providing increased strength and load-bearing capacity.

Diameter and Strength: Our Straining Wire Rope is available in various diameters to accommodate different load capacities. The diameter selection depends on the specific application and load requirements. We provide detailed specifications for breaking strength and working load limits for each diameter option.

Surface Finish and Coating: The wire ropes are typically finished with a galvanized or stainless-steel coating to enhance their resistance to corrosion, moisture, and environmental elements. The coating also provides a smooth surface for improved durability and reduced friction.

Features and Benefits

High Tensile Strength: Our Straining Wire Rope is engineered to withstand heavy loads and tension, ensuring reliable and secure performance in demanding applications.

Durability and Longevity: The use of high-quality materials and coatings results in excellent durability and resistance to corrosion, extending the rope’s service life.

Versatility: The wire rope’s strength and flexibility make it suitable for a wide range of applications, including rigging, lifting, anchoring, and tensioning.

Easy Installation: The wire rope can be easily installed using appropriate fittings, clamps, or tensioning devices, providing a reliable and efficient solution for various projects.

Compliance and Certification: Our Straining Wire Rope complies with industry standards and regulations for wire ropes. They are manufactured to meet or exceed the requirements of relevant national and international standards. Additionally, they undergo rigorous testing and quality control processes to ensure optimal performance and safety.

Please note that the specific product information and specifications may vary depending on the wire rope configuration, diameter, and customization options.

For detailed information and technical specifications related to your specific needs, we recommend contacting our sales team or referring to our product documentation.

For further assistance or to discuss your specific Straining Wire Rope requirements, please feel free to reach out to our dedicated team.

For additional documentation on the above products please visit our DOWNLOADS page.

- Additional information

Additional information

| Standard Diameters: | • 4mm • 6mm • 8mm • 10mm • 12mm |

|---|---|

| Standard Lengths: | • 50m Roll • 100m Roll • 1000m Reel |